Comec ACF200 CNC boring machine

The ACF200.CNC boring machine combines the two main operations of reconditioning the monoblocks of cars and trucks, such as boring and smoothing, in a single machine and now completely automatically thanks to CNC control.

The finest finishing and precision qualities that characterize it are the result of a combination of a proven mechanical design and the introduction of highly innovative technology solutions that make it smart even faster and more practical to use.

Standard equipment

- Computer Numerical Control using LINUX Operating System and ARMv8 CPU Processor

- Precision Ball screw drives on 3 Axis

- Movements by linear railways on 3 Axis

- Brushless motors on 3 axis controlled by CNC

- Swing arm control panel with double touch screens

- Electronic Handwheel for manual displacement on 3 Axis (Fast-Medium-Fine speeds)

- Full automatic and programmable working modes for boring and milling operations

- WI-FI and LAN connections for support and service

- PV0160 pair of parallel supports

- PV0021 large clamps (2 pcs.)

- PV0022 small clamps (4 pcs.)

- Wrench set

- Instruction manual

[table id=1 /]

Accessories and spare parts

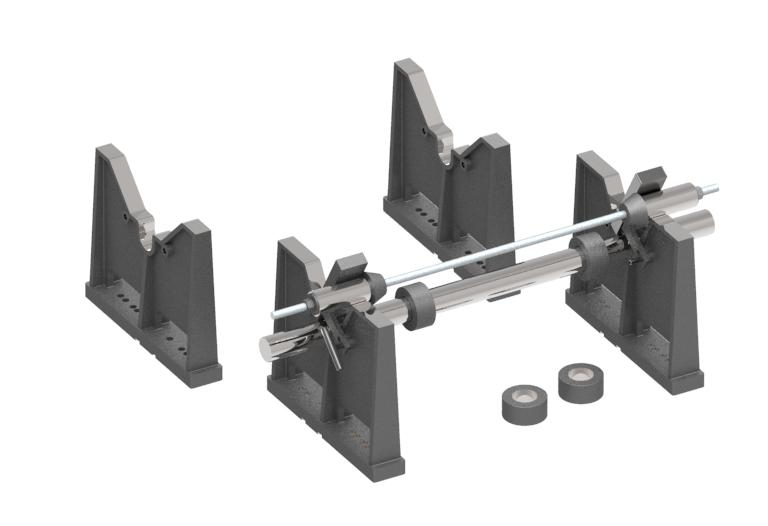

PV1516

60° – 90°V-block blueprinting mounting fixture

PV0025

Pair of fast clamping column

PV0160

Pair of parallel supports

UT1390

ALP insert tool holder for UT1392

UT1392

ALP insert for aluminum with prechambers

UT1320

3/8” CBN/PCD insert tool holder

B03560

Ø 35÷60 mm L = 330 mm boring kit with dial gauge adjustment

B06085

Ø 60÷85 mm L = 320 mm boring kit with dial gauge adjustment

C03560

Ø 35÷60 mm L = 330 mm boring kit with pre-setting system

C06085

Ø 60÷85 mm L = 320 mm boring kit with pre-setting system

C85170

Ø 85÷170 mm L= 360 mm boring kit with pre-setting system

B85170

Ø 85÷170 mm L = 360 mm boring kit dial gauge adjustment

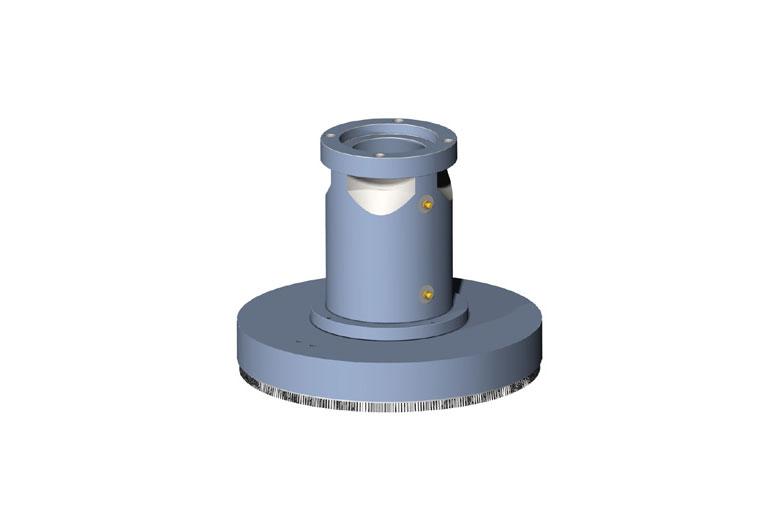

PF0320

1/2” CBN or PCD milling plate dia. 320 mm (available only for ACF)

UT1330

1/2”CBN/PCD insert tool holder

UT1345

3/8” CBN Insert for cast iron

UT1346

3/8” PCD Insert for aluminium

SSR200

Spindle storage rack